In the modern automotive industry, high-voltage test benches are essential to ensure the safety and efficiency of components such as batteries, inverters and electric drives. These test benches work with high voltages and currents and allow several test specimens to be monitored simultaneously. In the event of insulation faults, they ensure a safe shutdown.

The aim is to develop innovative and efficient system solutions for the drivetrain. These technologies are intended to increase the safety and reliability of electrical vehicle components and thus contribute to sustainable mobility.

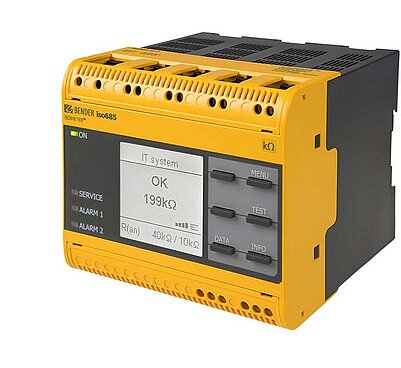

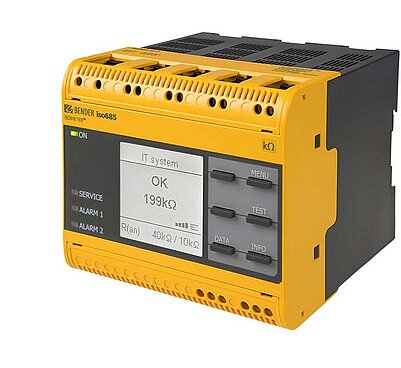

Advantages of the ISOMETER® iso685

In a specific project for a southern German car manufacturer, Schaeffler has developed high-voltage test benches that operate with up to 1,000 V voltage and 2,000 A current. These test benches can be used to test components such as batteries and electric drives safely and efficiently. They are designed to monitor several test specimens simultaneously and initiate a safe shutdown in the event of insulation faults.

When it came to selecting a suitable IMD (Insulation Monitoring Device), the ISOMETER® iso685-D was chosen. Positive experiences and the broad acceptance of these products were decisive factors in this decision.

Despite a tight time frame of just six months for the completion of the first series and global supply chain bottlenecks, the project was successfully completed. A total of 70 ISOMETER® iso685-D devices were integrated into the test benches. Further series productions are already in the works.

Products

Insulation monitoring device for inverter applications and large industrial plants

Insulation monitoring device for inverter applications and large industrial plants