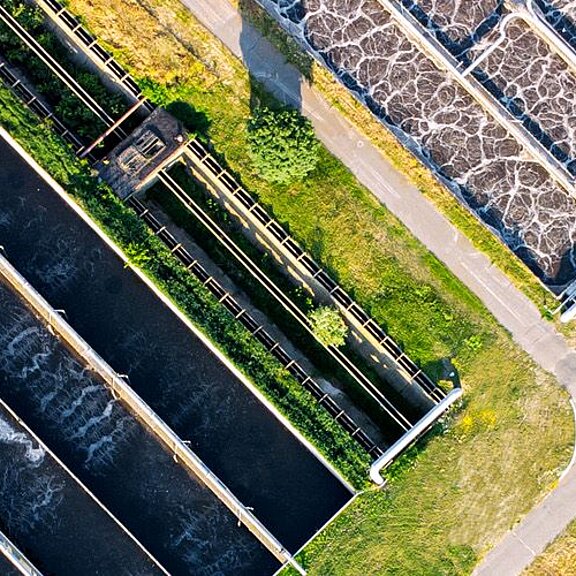

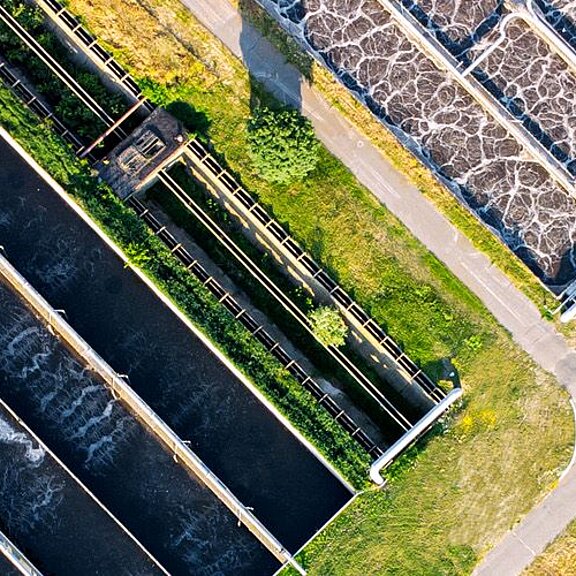

There are over 5,700 water supply companies and around 5,100 sewage treatment plants in Germany. Their task is to ensure the supply of clean drinking water to the approximately 82 million inhabitants in Germany and at the same time to dispose of and purify the waste water.

The Süderdithmarschen Water Association is responsible for this task between Heide and Brunsbüttel to the north-west of Hamburg. It supplies 60 municipalities with around 72,000 inhabitants over an area of 825 km2 with fresh drinking water. 28,000 m3 of water is pumped into the pipes every day. The Water Association also includes four sewage treatment plants that purify the waste water.

The Water Association Süderdithmarschen supplies 60 municipalities with around 72,000 inhabitants with fresh drinking water.

But why does a water and sewage treatment plant need residual current monitoring? At first glance, water and electricity have nothing to do with each other. A closer look reveals a different picture.

Water and sewage treatment plants are part of the critical infrastructure. This means that their services must be available 24 hours a day, 7 days a week.

To ensure that the water supply and waste water disposal function smoothly, many electrical consumers are required, for example pumps, drives for aerators, agitators, traction drives, valves and flow meters.

If even one of these consumers fails, the water supply or waste water disposal can be severely disrupted. Longer interruptions, which would be necessary for the periodic inspection, are not at all desirable, as they would impair the 24/7 supply.

Longer interruptions due to the periodic inspection impair the 24/7 supply.

The periodic inspection of electrical systems is more or less a challenge for every company. On the one hand, the inspection is very time-consuming and labour-intensive. Secondly, the electrical systems or system components must be switched off and disconnected from the mains supply for the measurement of the RISO insulation resistance.

This task cannot be accomplished with the electrical specialists employed by the Water Association Süderdithmarschen. This is because, on the one hand, systems would have to be disconnected from the grid for a longer period of time and, on the other hand, the electricians would not be available for their other tasks.

A solution therefore had to be found to reduce the time and effort required for electrical testing.

The recurrent test is very time-consuming and labour-intensive. A solution had to be found that reduced the effort involved.

When the water and sewage treatment plant was due for renovation, the majority of the switchgear was also to be replaced. The aim was to make the entire plant fit for the future and to take account of the increasing shortage of skilled labour. An important aspect of the modernisation was therefore to reduce the cost of the periodic inspection and avoid shutting down the water and sewage treatment plant. At the same time, all important measured values should be brought together and visualised in the monitoring centres.

With the specialised electrical planning Magnussen EMSR-Technik GmbH was commissioned. In order to be able to permanently monitor the electrical systems, they opted for residual current measurement technology from Bender. This is capable of permanently monitoring entire systems or parts of systems in earthed networks (TN system), i.e. 24/7. Residual current measuring devices can be used to detect residual currents in circuits and report critical values or failures centrally to the control technology. At the same time, permanent residual current measurement in electrical installations is recognised as a replacement for the time-consuming RISO measurement.*

In order to fulfil the requirements for holistic monitoring, the planning was carried out in such a way that the measurement technology monitors all important system components and consumers (pumps, valves, drives, flow meters, external lighting, etc.) individually. Only with granular monitoring is it possible to identify errors quickly and tie up fewer personnel. ** For the Süderdithmarschen Water Association, the concept of detailed and holistic monitoring was important in order to avoid the need for subsequent retrofitting.

* The German DGUV Regulation 3 states that the RISO measurement can be omitted from the periodic inspection of an electrical system if the system is continuously maintained by qualified electricians and checked by permanent or continuous metrological measures during operation.

Since last year, residual current measurement technology from Bender has gradually been installed in both the waterworks and the sewage treatment plants. The installation is carried out by the Water Association's electricians on the basis of the planning documents.

The LINETRAXX® RCMS150 multi-channel residual current monitoring devices are used to monitor drives, pumps and other important systems. These can monitor 6 circuits simultaneously and take up very little space in the switch cabinet. In addition, RCMB330 split-core measuring current transformers and CTUB102-CTBC20 AC/DC sensitive measuring current transformers are used.

The new SmartDetect residual current monitoring devices type LINETRAXX® RCMS410 are used as evaluation devices. These are particularly small, very flexible and can monitor 4 channels simultaneously. The COMTRAXX® COM465IP Condition Monitors/gateways were used as the interface. These handle the communication between the measuring devices and forward the data to the higher-level control system via Modbus.

Sewage treatment plant Meldorf

Sewage treatment plant Marne

Water Association Odderade

Status August 2024. The project has not yet been completed.

Get in touch with us! Our staff will be happy to help you.

TO THE CONTACT FORM