Risks due to high energy density

BESS are characterised by a high energy density, which significantly increases the risk of fire. In the event of an error, this can lead to intense fires that are difficult to control and cause considerable damage.

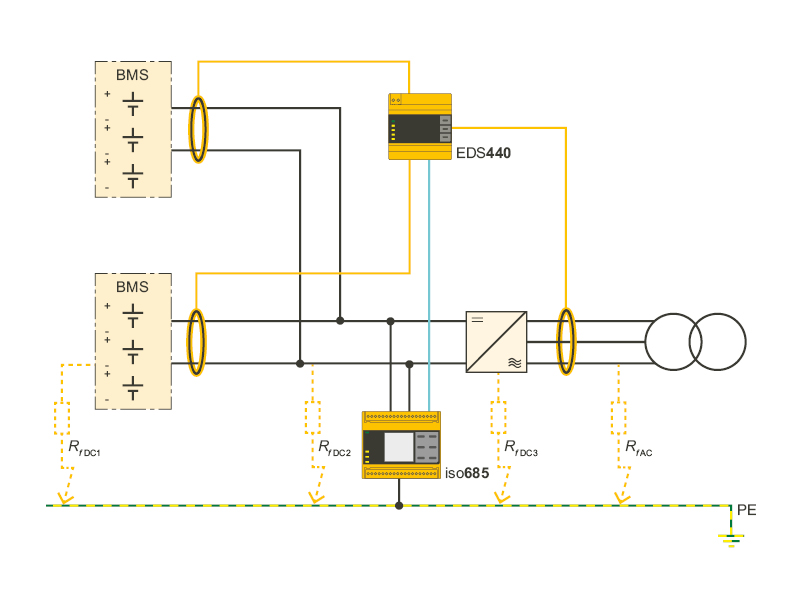

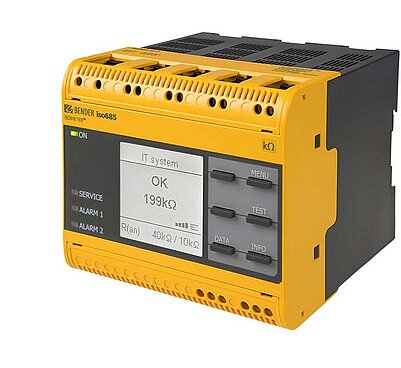

Battery energy storage systems (BESS) are often realised as unearthed systems (IT systems). In the event of a first fault, only a very low fault current flows in an IT system, which is largely dependent on the system leakage capacitance. This design ensures that the system remains safe and there is no immediate risk of continuing errors. This increases the reliability of operation.