Medium-frequency welding systems are used in many production systems. These are generally welding robots which are fitted with the corresponding welding tongs. Simple, efficient monitoring of the system requires visualisation of the fault current which is both meaningful and easy to interpret. This makes operating the system easier for the technical personnel and allows rapid response in the event of a fault. The AC/DC sensitive residual current monitoring devices (RCMA) from Bender are considered the leading technical solution. They are built into the feed system before the weld converter and thus monitor not only the weld current circuit for fault currents. This means they protect you reliably against personal injury and damage to machinery.

| Name | Category | Size | Language | Timestamp | D-/B-Number |

|---|---|---|---|---|---|

| Product Overview ISOMETER®/ISOSCAN® | Product Overviews | 5.3 MB | EN | 2024/02/1616.02.2024 | |

| Product Overview - Residual Current Monitoring | Product Overviews | 8.0 MB | EN | 2025/04/0202.04.2025 | |

| Electrical Safety in Control and Auxiliary Circuits | Technical article | 632.6 KB | EN | 2019/05/1313.05.2019 | |

| Electrical Safety and High Availability in Welding Systems | Technical article | 447.5 KB | EN | 2019/05/1313.05.2019 | |

| System Safety in Automobile Manufacturing | Technical article | 649.7 KB | EN | 2019/05/1313.05.2019 |

Products

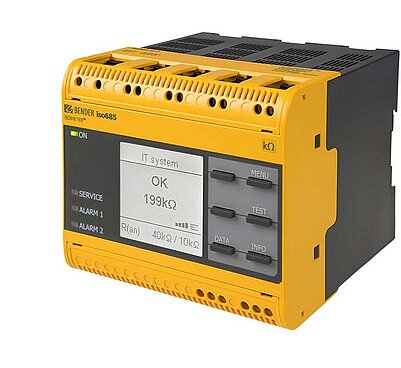

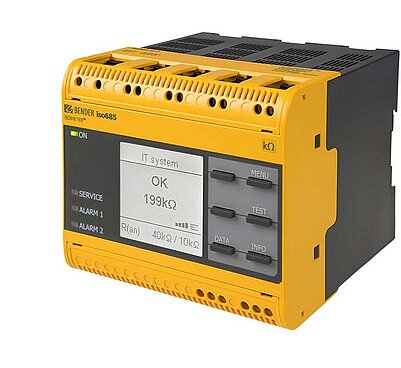

Insulation monitoring device for inverter applications and large industrial plants

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

Recognising connections – optimising maintenance

Insulation monitoring device for inverter applications and large industrial plants

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

Recognising connections – optimising maintenance

Electrical safety in low voltage distribution systems up to 1 000 v a.c. and 1 500 v d.c. - Equipment for testing, measuring or monitoring of protective measures - Part 8: Insulation monitoring devices for IT systems.

Electrical safety in low voltage distribution systems up to 1000 V a.c. and 1500 V d.c. - Equipment for testing, measuring or monitoring of protective measures - Part 9: Equipment for insulation fault location in IT systems

Electrical safety in low voltage distribution systems up to 1000 V ac and 1500 V dc - Equipment for testing, measuring or monitoring of protective measures - Part 15: Functional safety requirements for insulation monitoring devices in IT systems and equipment for insulation fault location in IT systems

Safety of machinery - Electrical equipment of machines - Part 1: General requirements

Electronic equipment for use in power installations