Pipelines are used to transport oil and gas across long distances. Pipe heating systems and other heating systems are also required in the process. These are monitored by type “B” Bender fault current systems. Any faults are reported immediately before a system shutdown becomes necessary.

In a compressor or condenser station, a compressor compresses the natural gas in order to compensate for pressure losses. The natural gas is stored at high pressure, and the pressure in the pipeline falls because of flow losses. The compressor is driven by a drive machine at up to 30 MW. These drive machines can be either gas turbines or gearless electric motors. For electric motors, frequency converters are required, which need to be monitored for their insulation levels or existing leak currents.

In order to cover relatively large distances, there are pump stations to pump the oil or gas. Since the pressure in the raw material to be transported is reduced due to flow losses, the aim of the pump stations is to increase pressure again. The pump is powered by gearless electric motors. This means frequency converters are required, and these need to be monitored for their insulation level or any fault current present.

Tank stores are stores in which fuels can be stored. Materials in the tank stores are often pumped around using large pumps powered by gearless electric motors. Frequency converters are normally used in the process to monitor insulation levels or existing leakage currents.

A tanker transports liquids or gaseous materials such as crude oil, oil as a finished product, fuel or liquid gas. Tankers have pumps for unloading and pumping around the load on board. These pumps are powered by gearless electric motors for which frequency converters are required to monitor for insulation levels or existing fault currents. One of the key components of shipping engineering is the main machine with its auxiliary generators, kettle systems, auxiliary diesel and the generators for power generation and loading pumps. The main distribution board on-board the tankers are generally designed as unearthed systems which are monitored with ISOMETER®s and fault locators.

| Name | Category | Size | Language | Timestamp | D-/B-Number |

|---|---|---|---|---|---|

| Product Overview ISOMETER®/ISOSCAN® | Product Overviews | 5.3 MB | EN | 2024/02/1616.02.2024 | |

| Product Overview - Residual Current Monitoring | Product Overviews | 8.0 MB | EN | 2025/04/0202.04.2025 | |

| Why the IT System is Often the Best Choice for Power Supply Systems of All Types | Technical article | 3.0 MB | EN | 2019/07/1111.07.2019 | |

| Electrical Safety in Control and Auxiliary Circuits | Technical article | 632.6 KB | EN | 2023/04/2121.04.2023 |

Products

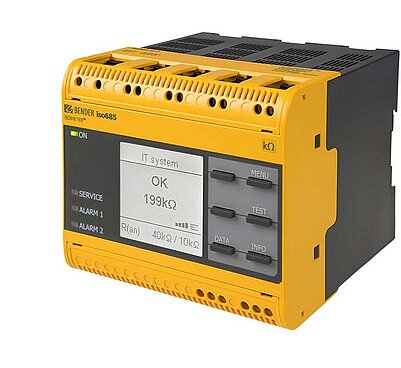

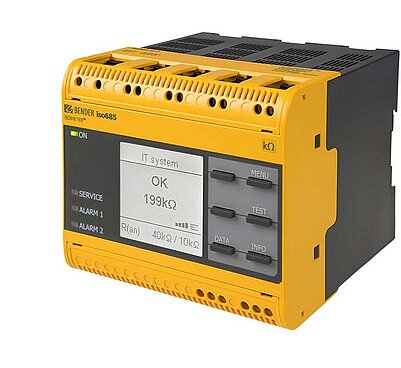

Insulation monitoring device for inverter applications and large industrial plants

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

AC/DC sensitive residual current monitor for TN and TT systems (AC, DC, pulsed DC currents)

![[Translate to English:] RCMA423](/fileadmin/_processed_/a/d/csm_RCMA423_01_WEB_2dc3226c4f.jpg)

AC/DC sensitive residual current monitor for TN and TT systems (AC, DC, pulsed DC currents)

Condition monitor with display and an integrated gateway

Recognising connections – optimising maintenance

![[Translate to English:] NGRM700](/fileadmin/_processed_/3/b/csm_NGRM700_01_WEB_list_97278228d7.jpg)

The advanced Neutral Grounding Resistor Monitor for sophisticated applications

![[Translate to English:] LINETRAXX® CTUB100 Series](/fileadmin/_processed_/0/d/csm_CTUB10x-CTBCx_WEB_SI_d8b0d156d2.jpg)

AC/DC sensitive measuring current transformer (Type B)

Insulation monitoring device for inverter applications and large industrial plants

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

AC/DC sensitive residual current monitor for TN and TT systems (AC, DC, pulsed DC currents)

![[Translate to English:] RCMA423](/fileadmin/_processed_/a/d/csm_RCMA423_01_WEB_2dc3226c4f.jpg)

AC/DC sensitive residual current monitor for TN and TT systems (AC, DC, pulsed DC currents)

Condition monitor with display and an integrated gateway

Recognising connections – optimising maintenance

![[Translate to English:] NGRM700](/fileadmin/_processed_/3/b/csm_NGRM700_01_WEB_list_97278228d7.jpg)

The advanced Neutral Grounding Resistor Monitor for sophisticated applications

![[Translate to English:] LINETRAXX® CTUB100 Series](/fileadmin/_processed_/0/d/csm_CTUB10x-CTBCx_WEB_SI_d8b0d156d2.jpg)

AC/DC sensitive measuring current transformer (Type B)

Electrical safety in low voltage distribution systems up to 1 000 v a.c. and 1 500 v d.c. - Equipment for testing, measuring or monitoring of protective measures - Part 8: Insulation monitoring devices for IT systems.

Electrical safety in low voltage distribution systems up to 1000 V a.c. and 1500 V d.c. - Equipment for testing, measuring or monitoring of protective measures - Part 9: Equipment for insulation fault location in IT systems

Electrical safety in low voltage distribution systems up to 1000 V ac and 1500 V dc - Equipment for testing, measuring or monitoring of protective measures - Part 15: Functional safety requirements for insulation monitoring devices in IT systems and equipment for insulation fault location in IT systems

Electronic equipment for use in power installations