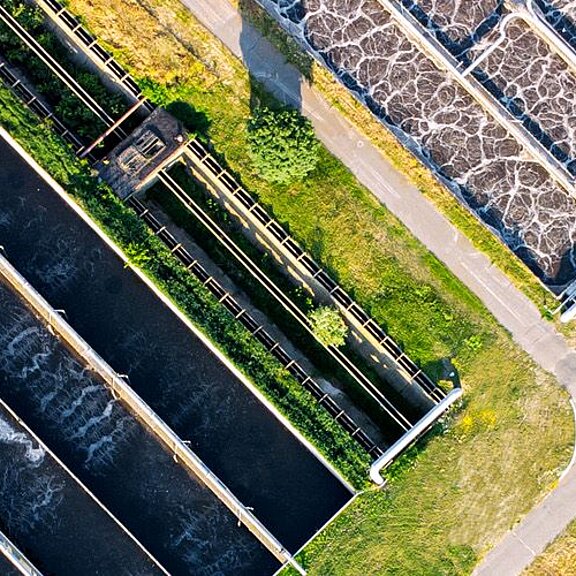

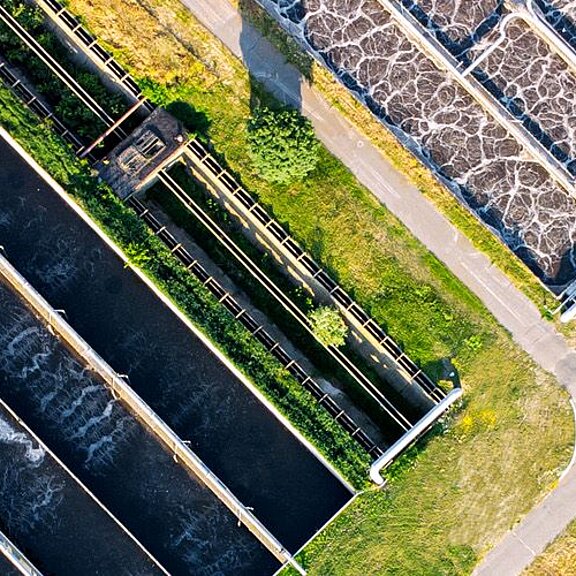

As part of the critical infrastructure, water and wastewater treatment plants have to run 24/7. There must be no failures. Failures and shutdowns are usually caused by insulation faults in pumps, drives, motors or their supply lines.

Such failures can be prevented with the right monitoring technology. Planned shutdowns for recurring inspections can also be avoided.

Read on to find out what solutions Bender has in store for you to keep your waterworks and wastewater treatment plant running without interruption.

For new installations, the use of an unearthed network (IT system) is the best choice. Insulation monitoring devices are used in unearthed systems to detect insulation faults.

Pumps, drives, agitators, valves, aerators, flow meters

Permanent monitoring

Recognising insulation faults at an early stage

First electrical fault without switching off

Automatic troubleshooting during operation

No switch-off for periodic inspection

Existing systems are usually designed as earthed networks (TN system/TT system). Residual current monitoring devices are used to detect insulation faults in earthed systems.

Pumps, drives, agitators, valves, aerators, flow meters

Permanent monitoring

Recognising insulation faults at an early stage

Prevent unplanned shutdowns

No switch-off for periodic inspection

Regardless of whether an earthed or unearthed network is used: Consumers that are only used very rarely can be monitored with special offline monitors.

Emergency slide valves and other important consumers that are usually switched off

Permanent monitoring

Recognising insulation faults at an early stage

No nasty surprises when switching on important consumers

Ensure operation of important consumers

The Süderdithmarschen Water Association near Hamburg (Germany) has been monitoring its waterworks and wastewater treatment plants since 2023 to ensure 24/7 operation and reduce the cost of periodic inspections. Read more here.

In Green Bay, Wisconsin (USA), a large wasterwater treatment plant for around 240.000 people was equipped with Bender technology in 2019 to ensure uninterrupted operation. Read more here.